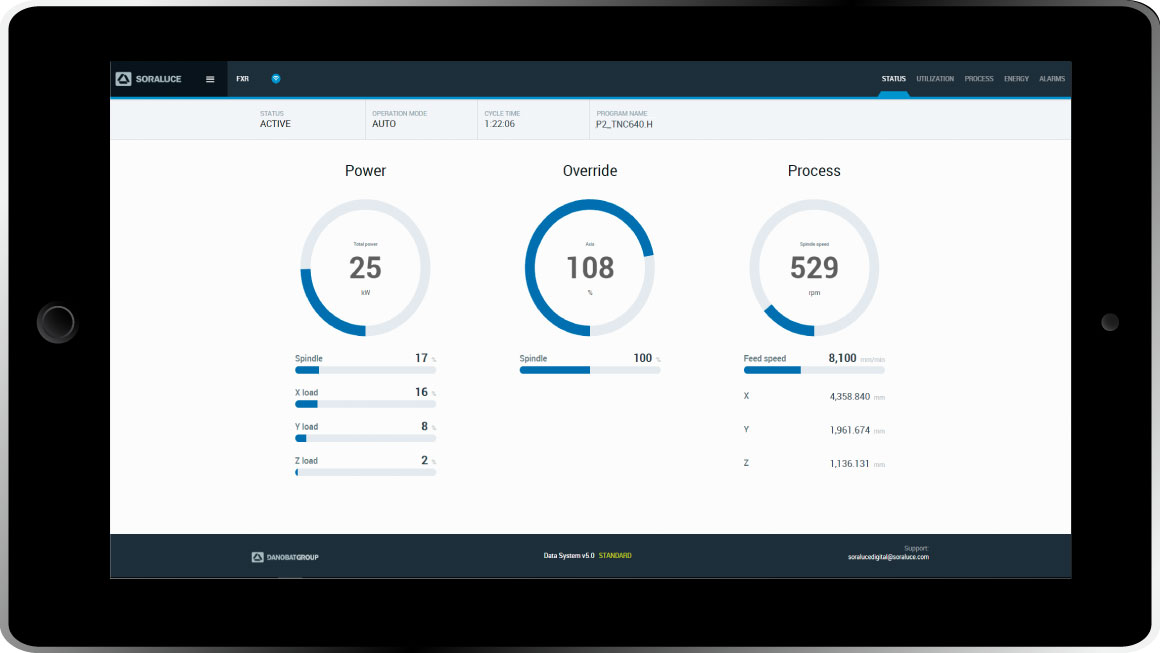

Comprehensive monitoring package which provides improved machine performance and an increase in process productivity, reducing operating costs.

Soraluce is improving its operational efficiency, connecting machines to a cloud enabling a seamless production information flow and maximizing machine performance. The interconnection of equipment and the possibility of obtaining and analyzing data from machines open up the path to creating smart manufacturing environments.

- Real-time information

- Anywhere, anytime, across multiple devices

- Establishment of patterns, identification of trends, and anticipation of faults

- Improved energy efficiency

- Under secure connection

Contact us

If you would like to receive information on our products, services or solutions, or for one of our collaborators to get in touch with you, fill in the following form.