PROBLEM TO BE SOLVED

Large raw parts (> 1m3) require time consuming Set-Up processes, even more than the machining process itself.

Before machining starts, it is required to:

- Assure there is enough overstock on all the surfaces to be machined

- Calculate raw-part alignment for optimal overstock distribution

- Locate and adjust the part in the machine

SOLUTION

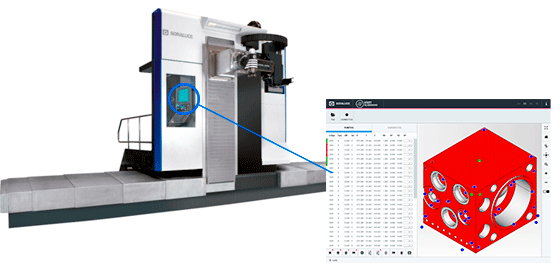

VSET is a new measuring system, based on 3D vision technology, which reduces the best fit calculation and alignment time of large raw parts.

The system is based on photogrammetric technology to measure the part thanks to different reference points located on the workpiece.

The information generated during the measuring stage is automatically compared to the 3D model of the part to calculate the best fit.

Once the raw part is validated it can be aligned in the machine using the same reference points.

BENEFITS

- Minimizes the row part alignment and setting-up processes time up to 70%

- Ensures the quality of the parts from previous processes such as foundries, forging and welding

- Increased machine availability and productivity, measuring and fitting process being executed outside the machine

- Easy to use: highly skilled operators are not required

- Low cost process

- Sufficiently precise measuring process

- Standardisation of machine alignment procedures

- Simple information available for machine operators

MODULES

Measurement of raw-part geometry by Photogrammetry technology

The measuring module is primarily made up of a set of optical markers and calibrated bars, a self-calibrating digital photogrammetric camera and a laptop computer, all of which are presented in security trolleys and cases that are easy to use in these industrial environments. The laptop has measurement software that is able to configure the point cloud of the geometry of the part based on photos that are obtained around the part.

- Comparison with CAD geometry

- Optimal overstock fitting and calculation of alignment references

- Report generation (pdf) for in-machine raw part alignment

The fitting module is a software development that is related to the measuring module, which, based on optimisation algorithms, almost immediately carries out 3D fitting calculations of the finished part, comparing them to the point cloud defined by the blank.

The result of this measurement and fitting is a reference report that will make it possible to align the machine in a simple way, using probing procedures that are usually already incorporated into the machine.

CNC integrated

This software module allows the automatic integration of fitting results into the machine control and, through calculation algorithms, makes it possible to carry out an automated, guided alignment process, facilitating and further reducing the time of this work.