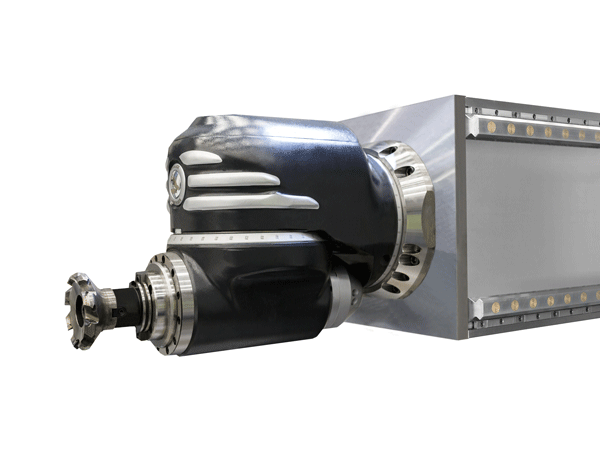

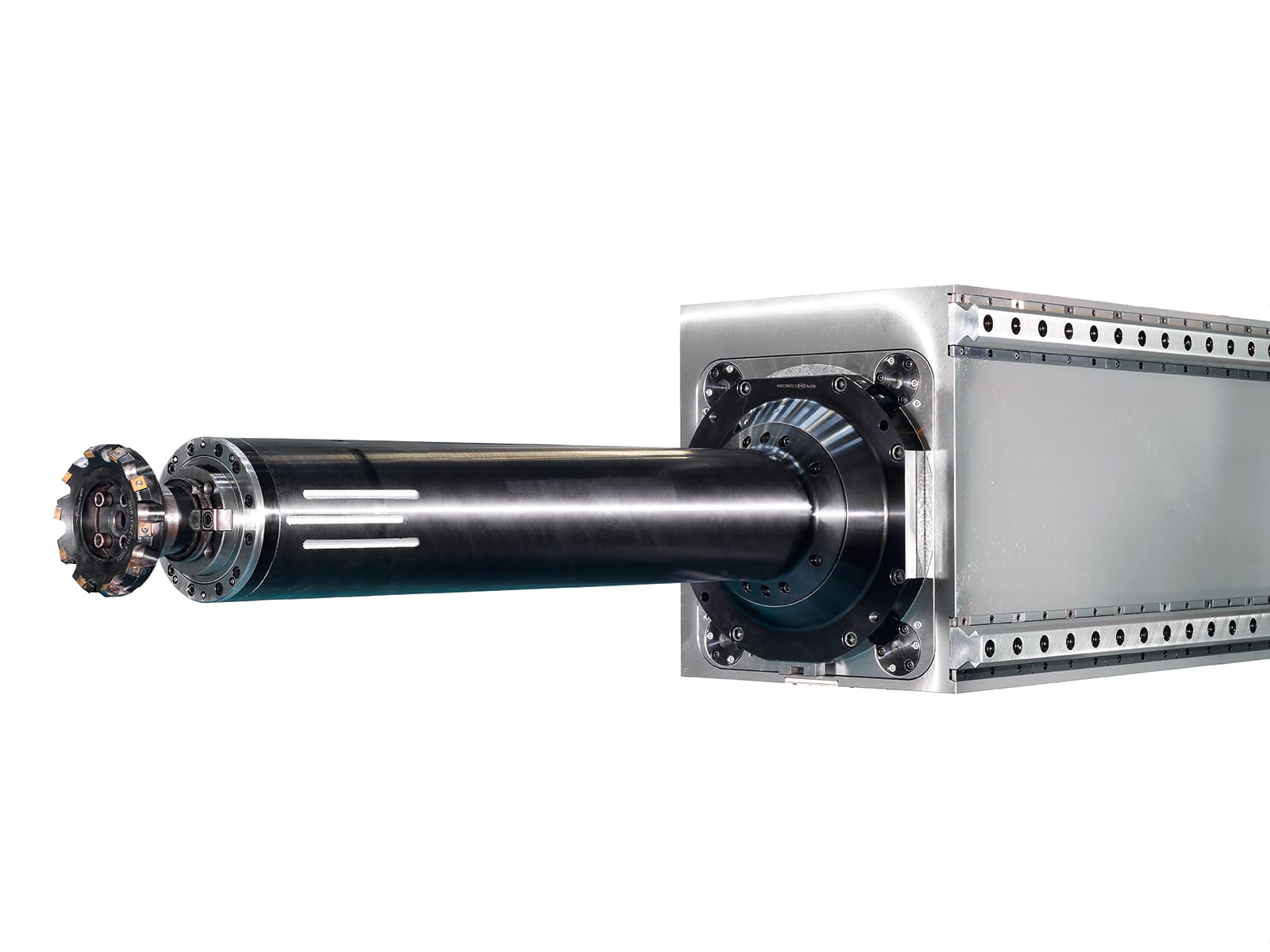

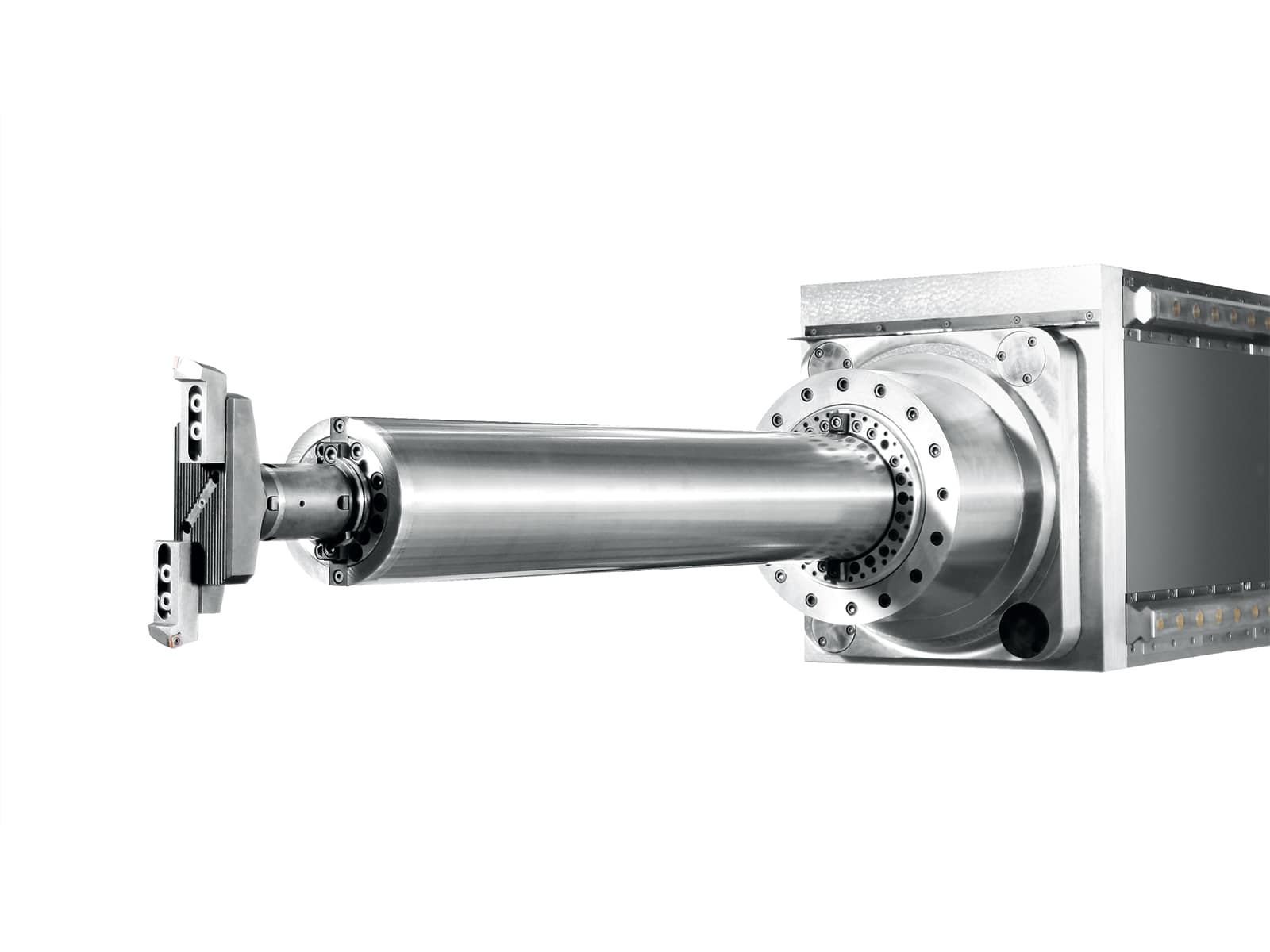

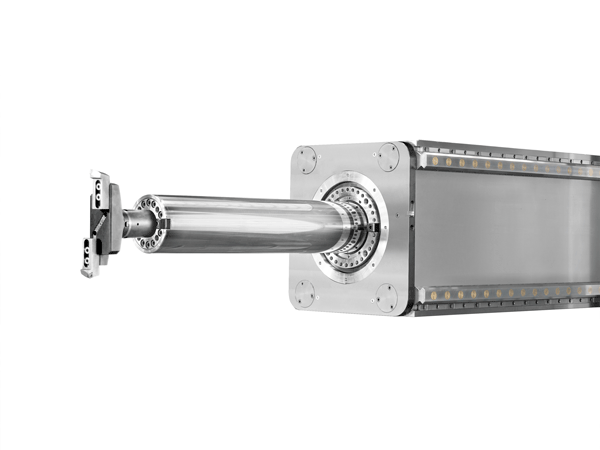

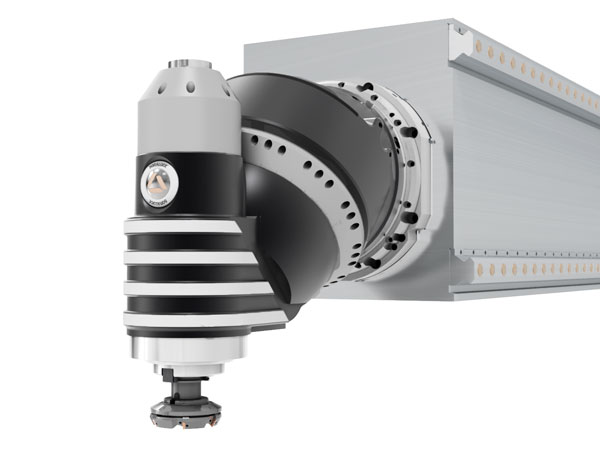

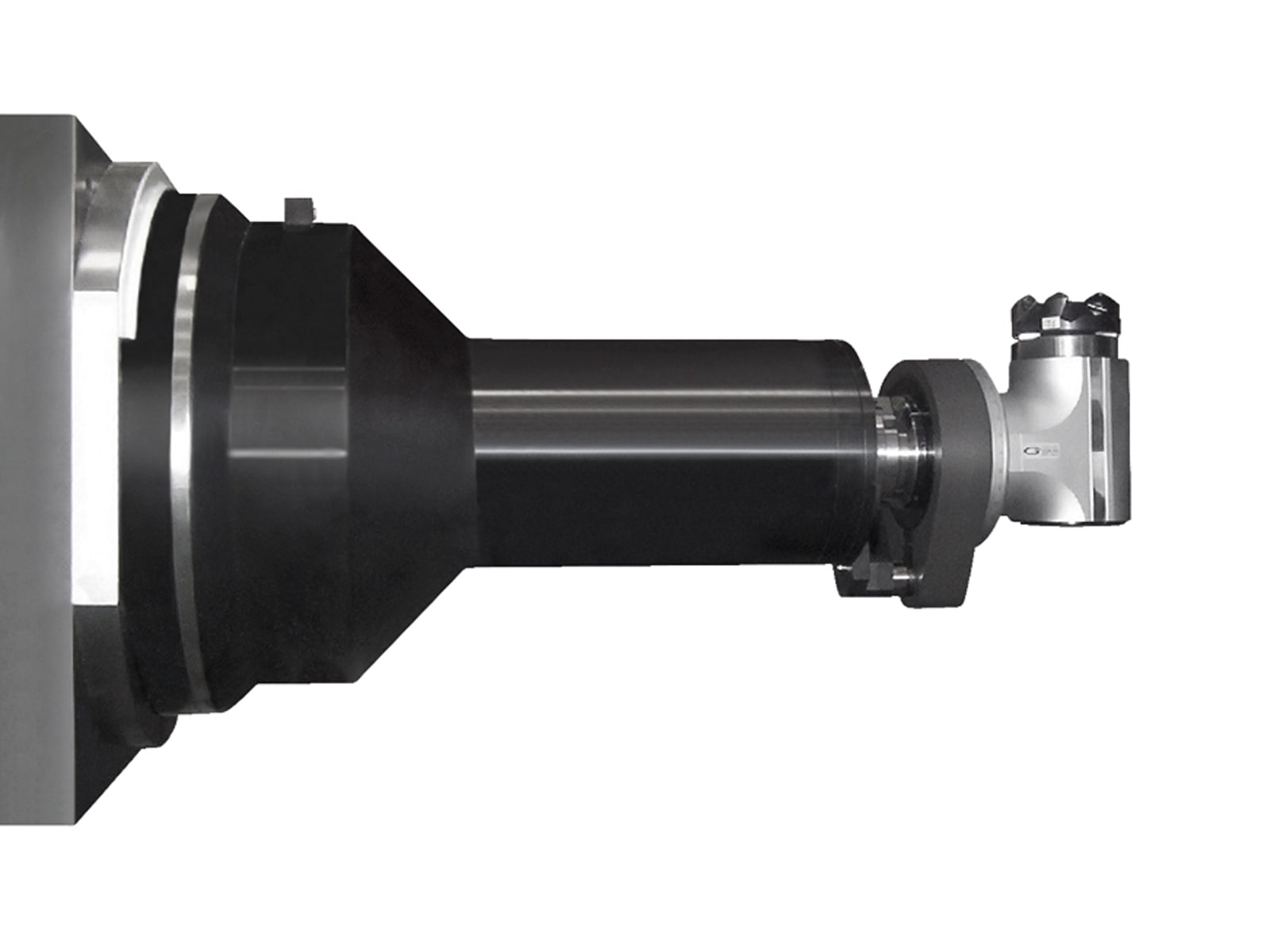

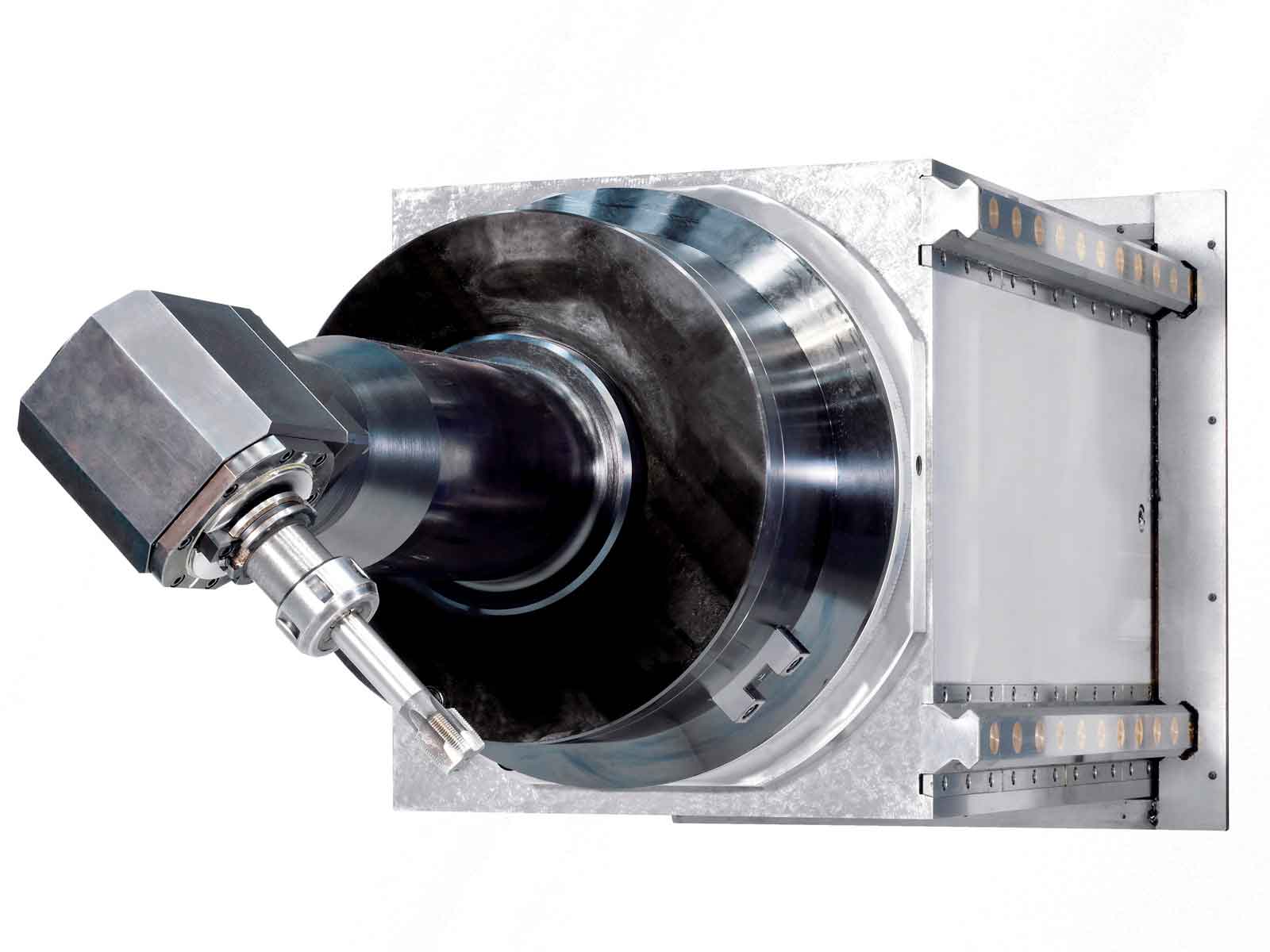

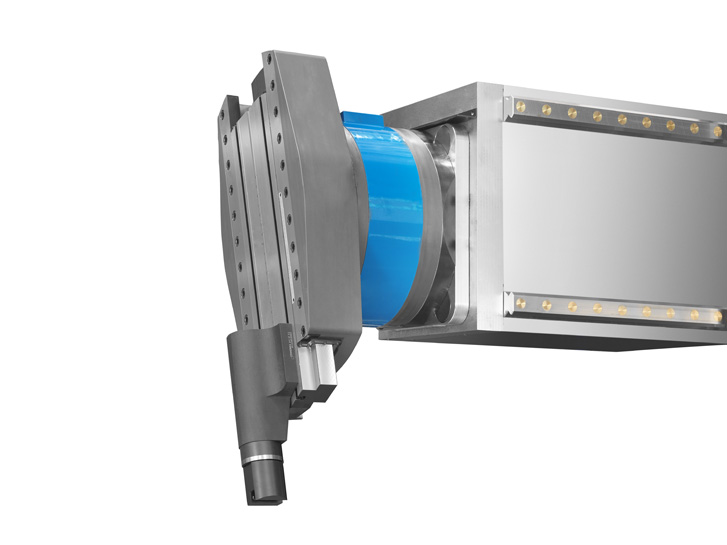

SORALUCE milling, boring and turning heads are acknowledged as being in a class of their own thanks to their high reliability. The broad range of SORALUCE heads are distinguished by their precision and high performance, enabling complex milling, boring, drilling, reaming and taping operations to be performed with great accuracy.

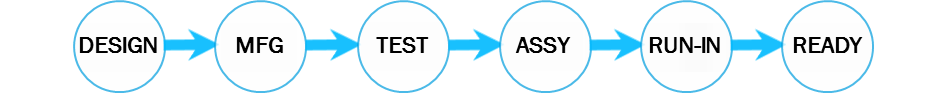

Complete design, manufacturing, assembly and verification processes are conducted in-house, under the same roof, by an experienced team of highly skilled designers and assembly engineers.

To ensure high quality heads, the workshop is equipped with state-of-the-art, temperature and humidity controlled, high precision manufacturing machinery and assembly equipment. With strict in-process quality controls and exhaustive run-off on specific test benches, SORALUCE certifies the highest quality for the most critical elements on this kind of machines.

In order to cater to the diverse needs of each customer, SORALUCE’s contrasted head technology is fundamental and provides the necessary customisation for an optimal configuration, with the possibility of including a large variety of standard heads and special solutions.

- Top class heads

- High precision and reliability

- In-house designed and manufactured

- Broad range: 50 standard / 70 special