SORALUCE TR-M multitasking centre

- High performance capacity in milling, turning and grinding in a single set-up.

- Advanced SORALUCE technology geared towards maximising productivity, precision and customisation: DAS+, Chip Breaker, DPS, DHC, Accura Heads and Adaptive Control

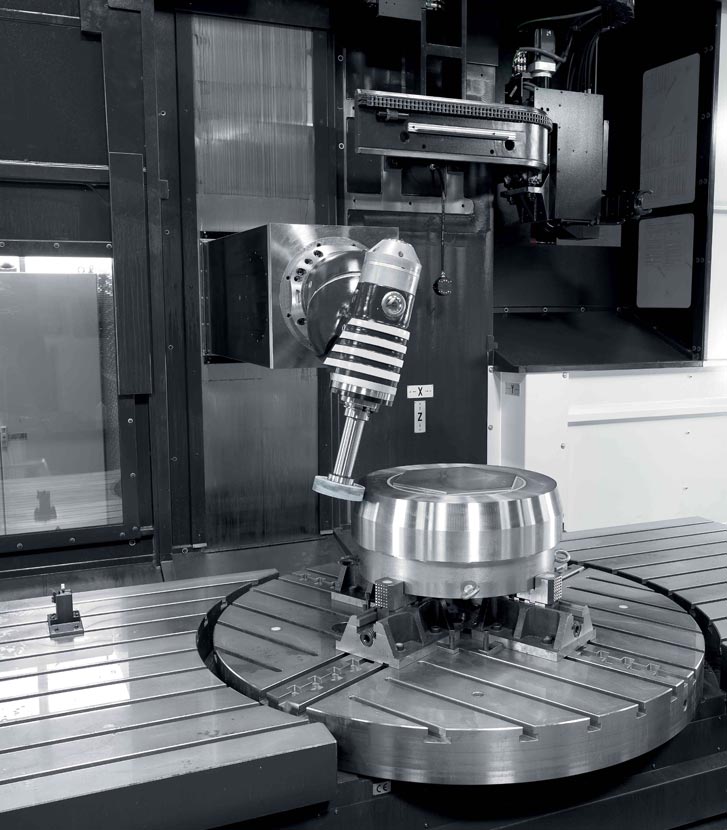

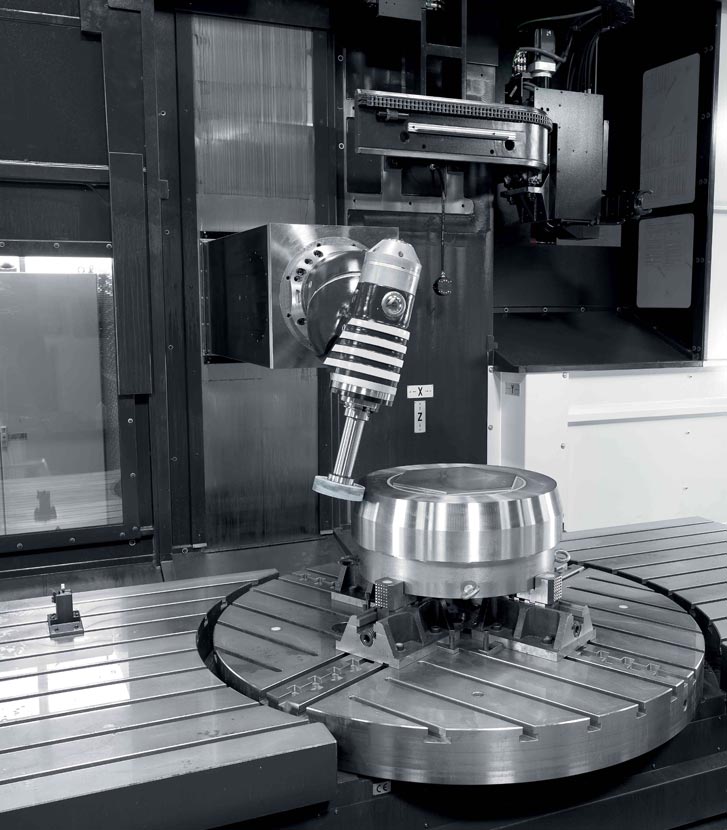

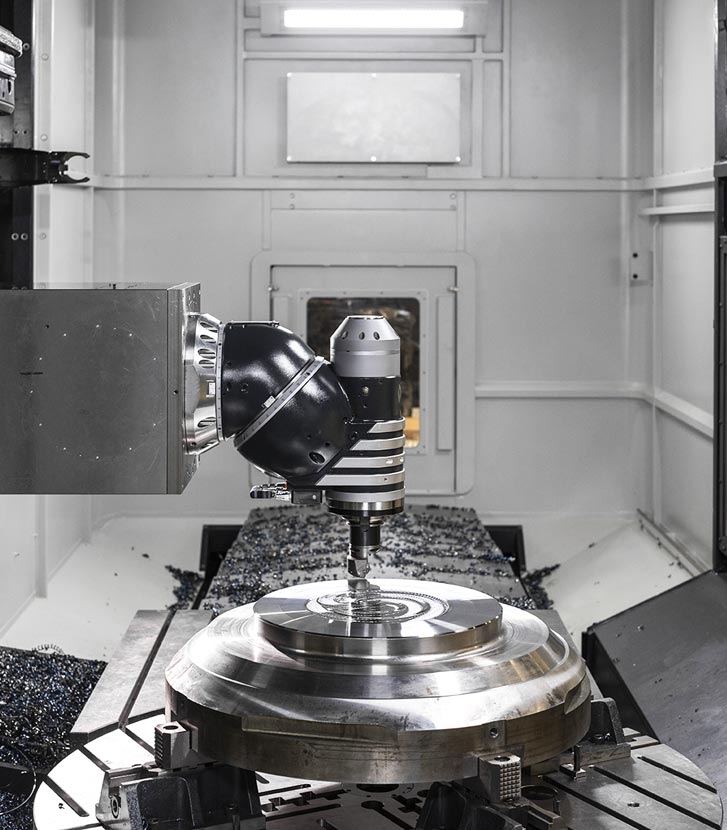

- Multitasking machine: a milling, turning and grinding solution in a single set-up

- Ø 1600 / 1400 mm turning table for turning and milling operations

- Heavy duty machine, supporting workpiece loads of up to 10,500 kg for milling and 3,250 for turning and grinding

- SORALUCE head technology: a highly reliable, extensive range of SORALUCE multitasking, enabling milling, turning and grinding operations

- Automatic tool changing system

- Specific cycles for grinding

- SORALUCE Digital, Data System: a comprehensive monitoring package with continuous information of machine and process status

- Long-lasting precision, resulting from a strict design and assembly process

- Optimal stiffness and mechanical stability, providing high stock removal capacity for roughing operations

- Great precision and efficiency with the high torque, direct drive spindle motor

- High dynamics with speeds of up to 35 m/min, acceleration of 2 m/s2 and working feed force of 16000 N on all axes

- Enhanced productivity and precision for components belonging to the moulds and dies and precision engineering industries

- Total machine concept design: complete working area analysed for optimal comfort, safety and ergonomics (maintenance spots, operator area)

|

Characteristics |

TR-M 30 |

TR-M 35 | |

|---|---|---|---|

|

Table area |

mm |

Ø 1600 |

3500 x 1450 (Ø 1600) |

|

Swing (max) |

mm |

Ø 2300 |

|

|

Table speed range |

min-1 |

10 ÷ 400 |

|

|

Table spindle power |

kW |

81 |

|

|

Table capacity |

kg |

10500 by milling / 3250 by turning |

|

|

Longitudinal traverse "X" axis |

mm |

2500 |

3500 |

|

Vertical traverse "Z" axis |

mm |

16000 |

|

|

Cross traverse "Y" axis |

mm |

1300 / 1500 |

|

|

Spindle power |

kW |

43 |

|

|

Spindle speed range |

min-1 |

4000 / 5000 / 6000 / 7000 |

|

|

Rapid traverse |

mm/min |

35000 |

|

|

Tool magazine |

Nº Tool |

20 / 40 / 60 / 80 |

|

Customisation

Select your head:

Technical data

- Automatic indexing head with turning capabilities

- Up to 4000 rpm with standard steel bearings, or 5000 rpm with hybrid bearings

- Air-oil lubricated gears

- The head includes a clutch in the spindle area for positioning and clamping the spindle at any angle for turning operations. The clutch hydraulically clamps and unclamps the rotation of the spindle for turning operations

- Possibility of working with bigger diameter workpieces, performing turning operations in a diagonal direction (interpolation X/Z axes)

- The head can be positioned to avoid interferences with the workpiece

- The use of this head is highly recommended on multitasking machines (milling and turning)

- 37 kW

- 2.5° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 min-1

Technical data

- One or two plane Indexing with orthogonal layout

- Capable of cutting in continuous rotation and with articulations locked

- Various types of chuck available: ISO-50, HSK-68 & HSK-100