Soraluce to Showcase New State-of-the-Art Milling Machines at BIEMH

˗ Soraluce will exhibit the latest advanced milling, boring, multitasking and automation solutions from its exhibition space (Hall 1, Stand C09).

˗ The company will introduce new products: the Performance Line, offering the best reliability and precision ratio with exceptional flexibility for medium-large parts; and, in a world premiere, the Dynamic Line, featuring high rail gantry machines aimed at specific applications in the aerospace and mould & die industries, with extensive possibilities in general mechanical engineering applications.

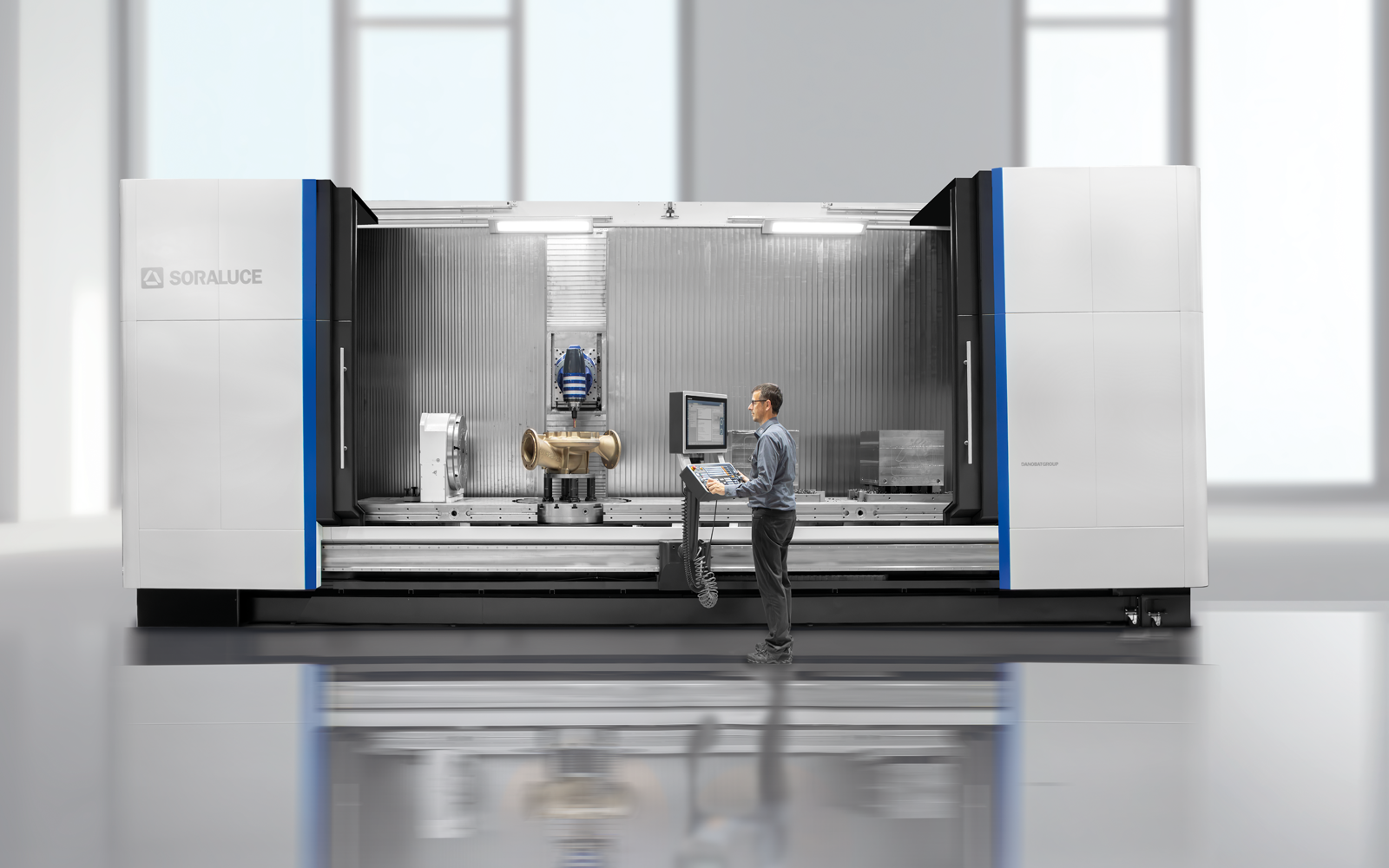

˗ Soraluce will display, onsite, the new fixed-table travelling column milling machine SAD, where live machining tests and demonstrations of their proven smart active damping technologies, DAS and DWS, will take place.

Soraluce will showcase its drive for progress at BIEMH 2024, focused on its firm commitment to maintaining technological leadership through innovation, specialization, growth, sustainability, and over 60 years of industry expertise.

At the forefront of technology and specializing in the manufacture of milling, boring multitasking and automation solutions, the company will once again be present at the upcoming edition of the Biennial International Machine-Tool Exhibition (BIEMH), which will take place from June 3 to 7 at the Bilbao Exhibition Centre (BEC) in Barakaldo (Bizkaia) in Hall 1 Stand C09, alongside Danobatgroup.

In a landscape where industrial sectors increasingly require advanced technological solutions to face future challenges, Soraluce has taken a step forward by expanding its range of milling, boring, multitasking and automation solutions.

Thus, the machine tool manufacturer has chosen to incorporate two new lines of milling machines into its product portfolio. This will allow it to respond to the challenges of the machine-tool sector, providing high added value solutions in the most demanding industrial environments. At BIEMH, the company will present its expanded range of milling machines with the new Performance Line and Dynamic Line, and will have the new fixed-table travelling column milling machine SAD40 on-site, where live machining tests and demonstrations of their proven smart active damping technologies, DAS and DWS, will take place.

New Performance Line. Born Reliable. Born Precise.

The new Performance Line provides the highest reliability and precision along with an outstanding flexibility for medium/large workpieces.

A common structure, three different types of architecture and countless solutions to adapt to the needs of each of our customers in the most competitive manner possible.

Each of these families caters for several models and configurations (fixed table, rotary table, multitasking), producing machines that can be configured for different work environments. These are 3 ranges sharing the main machine features, such as the column, saddle, ram and heads, built on the principle of modular design, to give us high reliability, easier service and flexibility to devise a solution for the customer.

Performance Line has the same design principles as SORALUCE´s heavy-duty machine range: Soraluce Winning Combination, providing the most rigid and dynamic solution available on the market, with a combination of a cast iron structure, linear guides and active/passive damping technology.

It applies all the experience the manufacturer has gleaned from its larger models, and has chosen the solution to offer more precision and reliability: direct drive inline motor with high power and torque in the ram, equipped with a 32 kW motor capable of reaching rpms up to 8000. The motor is water-cooled to boost thermal stability and secure the best precision machining results.

As an example of this new range, Soraluce will showcase, in situ at the BIEMH fair, the new SAD40 fixed-table travelling column milling machine. With a 4000 mm longitudinal traverse, a 1500 mm vertical traverse and a 1200 cross traverse, it has a 4000 x 1000 mm table with an integrated rotary table with diameter 1000 mm. The SAD40 has a compact design, and is a machining unit with a mechanical head, with high dynamics on all axes and splendid user ergonomics, accessibility and safety. The machine has a number of stations for work in pendulum mode, thereby eliminating idle time. The SAD has full enclosure, with front access to the workpiece and the workpiece at user height, as a totally ergonomic solution. The machine also features SORALUCE´s smart technology systems, such as Accura Heads, DAS™ and Data System.

New Dynamic Line. Step into Precision & Dynamics with the New Soraluce High Rail Gantry Machines

Soraluce will unveil, in a world premiere, the launch of its revolutionary Dynamic Line, which includes new high rail gantry machines. This new line embodies precision, dynamics, and efficiency, aimed at revolutionizing manufacturing processes in various industries.

Soraluce’ s high rail gantry machines are designed to deliver unprecedented performance in manufacturing complex and high-precision components. These machines offer high speed cutting, great precision rates and high-volume machining capability, backed by Soraluce’ s extensive experience in the milling sector and proven state-of-the-art technology.

The Dynamic Line consists of three machine models focused on applications in the aerospace sector, moulds and dies, or mechanical engineering, with solutions designed for specific materials: composites, light alloys, or steel.

These machines can be equipped with 5-axis milling heads, both gyroscopic and high-torque. This type of head provides the versatility necessary for correct handling of complex-shaped parts. Additionally, the machines feature a complete splash protection system (total enclosure) to maintain cleanliness and safety standards in the work environment.

Furthermore, the incorporation of various dust extraction systems, both in the enclosure and directly integrated into the heads, facilitates the removal of composite residues generated during machining. This aspect is crucial from the perspective of operator health protection (preventing the inhalation of toxic fumes) and also and also helps to keep the work area clean.

Key features of the high gantry machines include:

Unprecedented efficiency thanks to high dynamics and large cutting capacity at high speeds offered by the machines within the Dynamic Line. With speeds of up to 60,000 mm/min and accelerations of up to 4 m/s², these machines are designed to push productivity limits.

Innovative 5-axis contouring heads, with speeds of up to 30,000 rpm. It´s not just about offering fast positioning but enabling that movement with precision and delicacy. By equipping these heads, Soraluce’ s customers can machine parts with sophisticated designs and complex geometries. Whether shaping an aerospace component or machining complex moulds or dies, semi-finished and finished in steel or aluminium, the high dynamics of these machines ensure that these machining operations are executed with unparalleled precision and efficiency.

Dynamic Line offers the best surface finish quality for the most demanding jobs. In precision engineering, every detail matters, and achieving impeccable surface finishes is paramount. With the Dynamic Line, excellence is not just a goal but a guarantee.

One of the cornerstones of this commitment is thermal stability, ensuring that the machine’s precision and performance remain constant despite temperature fluctuations and rigorous machining tasks. This stability is more than just a feature; it is a testament to the innovative engineering that underpins all aspects of design and manufacturing of all Dynamic Line machines. Moreover, it is key to ensuring long-lasting machining at high speeds without compromising finish quality or performance, providing uniform results time and time again.

At the heart of cutting capability are our high-power mechanical heads, designed to deliver unmatched power of up to 60 kW. This extraordinary power ensures optimal performance, allowing users to tackle even the most demanding cutting tasks with ease and precision. Our solution offers a wide range of these mechanical heads, including high-torque 5-axis contouring (up to 2000 Nm). This versatility allows users to carry out complex machining operations with unprecedented precision, enabling them to tackle current and future challenges across a wide range of applications in various sectors.

About Soraluce

With a wealth of experience based on 60 years of history, at Soraluce we have revolutionized the world of machine tools, innovating and creating our own technology, producing innovative ground-breaking solutions in the field of engineering, with a clear objective - to lead the market in order to enable our customers to lead theirs too.

Soraluce´s success is based on excellent quality, the best possible service, in-house state-of-the-art technology, the technological capacity to customize each product in accordance with the individual requirements of the customer, and a fully international outlook. The strength of our offer is based on an unwavering commitment; to provide innovative solutions committed to the technological progress of our customers, responding to the most demanding machining challenges with efficiency and high levels of productivity.

The Soraluce Premium Solutions are a perfect combination of a quality product, sturdy and reliable, state-of-the-art technology and the latest digital developments, backed up by personal human service. We place the emphasis on our products, with an extensive range of milling & boring machines, vertical lathes, multitasking solutions and automated lines and systems, providing reliability, high productivity, precision, durability and premium quality. Moreover, our major asset, our technology, in-house technological products, digital services and customized manufacturing solutions which boost the performance of our products and services and offer unbeatable potential for our customers in terms of productivity, efficiency and profitability. And we provide all this with the best possible service and professional advisory in machining engineering, with an up-close-and-personal attitude that makes us the perfect partner.

Success, however, also means constant growth in both quantitative and qualitative terms, encompassing the human, social and economic perspectives. Year after year, Soraluce means more. More people, more qualifications, more research and more technology, more space for expansion, and more sustainably as well. Our expansion can be expressed in figures, with over 3,000 machines sold, and almost half of them in Germany, an extremely demanding market. 75 contact points worldwide, and over 400 people who give the very best of themselves every day. And the best figure of all, 80% of customers who place their trust in us once more, setting their sights once more on leadership of their markets.

All this growth, however, would be impossible without somewhere to grow, and so at Soraluce we are committed to sustainability through positive initiatives such as the construction of our new plant, LEED-certified for its sustainability. We were the first European machine tool business to secure this certification.

And finally, we can also boast the security of solid support, because working with Soraluce means working with a solvent partner. We form part of Danobatgroup, the machine tool division of Mondragon Corporation, one of Europe´s largest business groups. Danobatgroup has Excellence Centers in Germany, Italy, the USA, China and the UK, and its own R+D Center staffed by 120 engineers and 29 Ph. Ds, a facility that goes back more than 30 years. Danobatgroup provides one of the market´s most comprehensive and competitive multi-technology offers. With a headcount of 1,300 employees and a turnover of 277 million euros, it has a clear focus on innovation, investing approximately 9% of revenue in R+D+i.

There is only one first