SORALUCE at BIEMH 2026: Leading Capabilities in Large-Scale Machining Solutions

On the occasion of BIEMH Bilbao, to be held from March 2 to 6, 2026, at the BEC exhibition center, Soraluce strengthens its positioning as a benchmark industrial partner for the development of advanced machining solutions. The company will present a differentiated offering in large-capacity machines, aimed at maximizing productivity, precision, and efficiency in strategic industries.

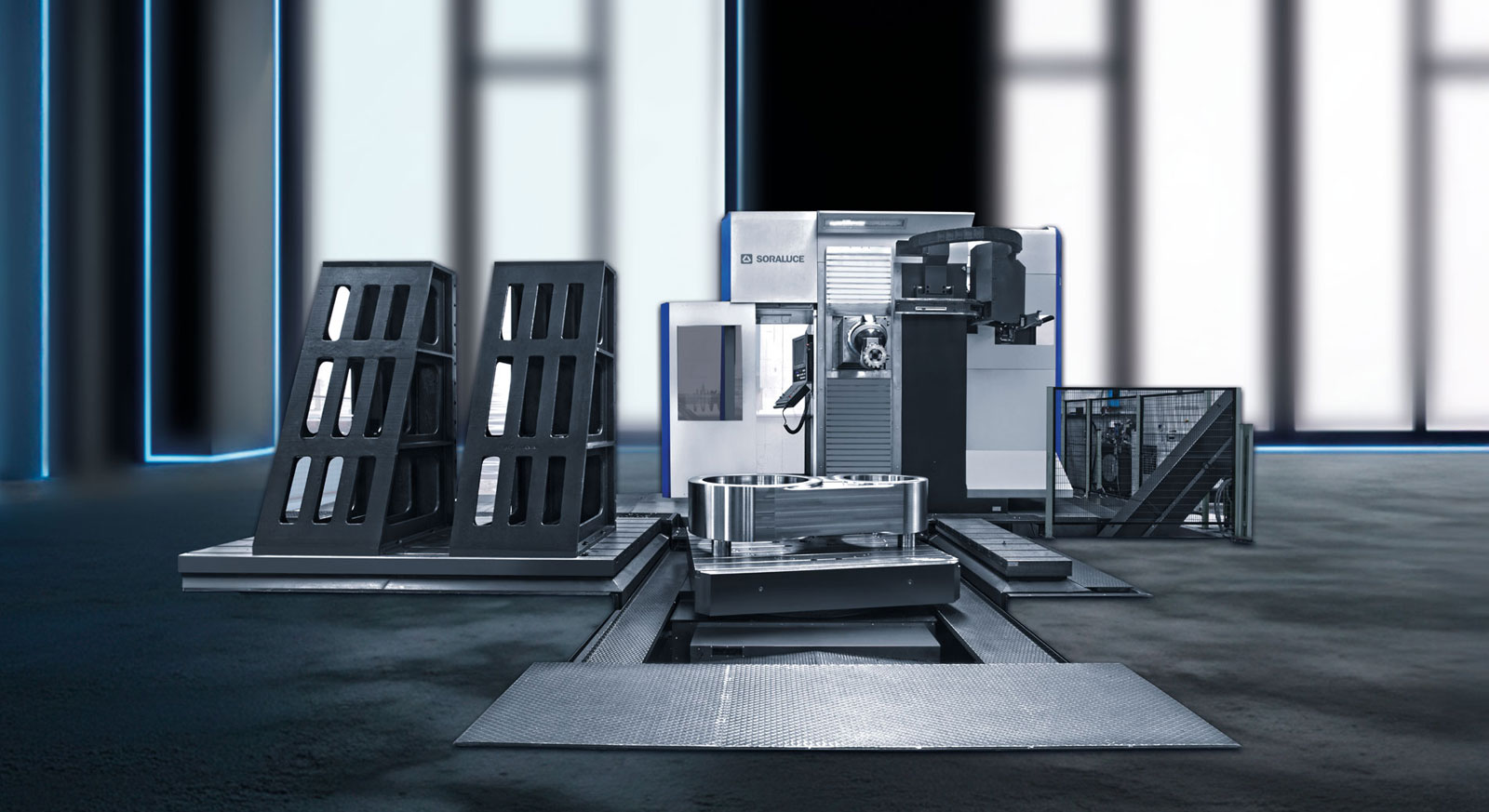

At its stand, Soraluce will showcase its capability to develop solutions for machining large components, supported by a broad range of milling machines, boring mills, vertical lathes, multitasking machines, and automation solutions. This proposal is designed to meet the growing demand for flexible, multi-part production in complex industrial environments.

These solutions are engineered to address the constantly evolving challenges of key sectors such as aerospace, energy, and mold and die, anticipating a future that is increasingly automated, connected, and data-driven.

Soraluce will be exhibiting at BIEMH – Hall 1, Stand C10, within the Danobatgroup space, the industrial group to which it belongs, alongside Danobat.

A Leading Partner in Large-Scale Machining Solutions

Soraluce positions itself as the manufacturer with the greatest development and customization capabilities across milling machines, boring mills, multitasking machines, and automation solutions, especially focused on machining large, high-complexity components.

Thanks to its applied engineering approach, the company goes beyond the supply of machine tools, developing tailor-made solutions that integrate mechanics, technology, automation, software, and services—always adapted to each customer’s real production processes.

Within this context, Soraluce presents its Smart Automated Solutions, designed to maximize productivity and reduce non-productive time throughout the entire manufacturing process by integrating the machine, palletization, process, automation, tool management, and software into a single ecosystem.

Productivity Line: Highly Flexible and Productive Milling-Boring Machines

At BIEMH, Soraluce will present the FLP80 floor-type milling-boring machine, a representative model of its Productivity Line, designed for machining large parts with high material removal capacity, cutting stability, speed, power, and precision. Its modular architecture allows multiple configurations and customization options, with several workstations and pendulum machining to minimize non-productive time.

The FLP80 features traverses of 8,000 mm on the X-axis, 2,200 mm on the Y-axis, and 1,600 mm on the Z-axis, and is equipped with a 43 kW spindle delivering up to 7,000 rpm. It incorporates an automatic universal head with 2.5° × 2.5° positioning and advanced technologies such as the DAS active damping system, adaptive control, and spindle interpolation for turning operations.

Shaping Progress in the Aerospace Industry

As a third pillar of its presence at BIEMH, Soraluce will feature a dedicated space for the aerospace sector, showcasing its capabilities in machining aerostructures, engine components, and landing gear. Its offering is supported by technologies such as 5-axis machining, active damping, multitasking, intelligent automation, and process monitoring.

Highlights within this offering include High-rail Gantry Machines, focused on machining large structural components with high cutting speeds, extreme precision, and process stability, as well as Soraluce’s new fork-type head. This five-axis solution is designed to ensure maximum precision, stability, and flexibility when machining advanced materials and complex geometries. With power ratings of up to 100 kW and speeds of up to 30,000 rpm, it significantly expands the versatility of the company’s aerospace solutions.