Smart damping solutions to boost stock removal capacity during machining

- SORALUCE has developed smart vibration control systems for better stability during the machining process

- The machine tool manufacturer has designed solutions to eliminate chatter from a general perspective, in due consideration of the potential sources of this problem, including the machining of flexible parts

- The company also offers engineering services to devise customised solutions

- All these developments will be presented at the company´s TECHNOLOGY DAYS event from 12-16 November at its Excellence Centre in Germany

Machine tool productivity is often associated with material removal capacity. A number of parameters, some relating to the machine itself, such as its power output and dynamics, and other process-related criteria such as the tools, the material to be machined and the part itself determine the removal rate that may be obtained. However, it is normal to come up against problems concerning vibration. This can limit the predefined machining conditions, and lead to noise problems, poor finishing or even tool breakage. Elimination of chatter is a challenge for any operator.

In a bid to take up this challenge, machine tool manufacturer SORALUCE has developed a number of solutions to eliminate self-excited vibration or chatter, boosting machines´ cutting capacity and improving the efficiency of machining processes.

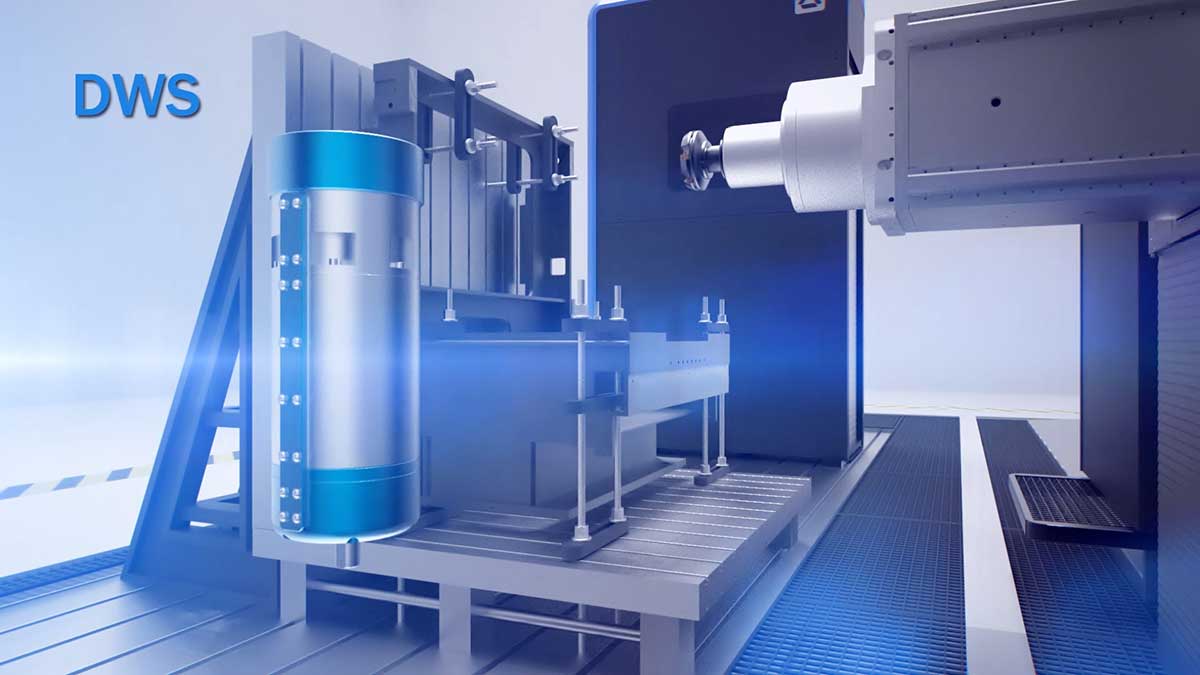

Specifically, the team of dynamic behaviour experts at SORALUCE and its technology centre IK4-IDEKO has developed the Dynamic Workpiece Stabiliser (DWS). This system eliminates the chatter which usually occurs when flexible parts are being machined. DWS, patented, is an active damping device which consists of a controller and one or more inertial actuators placed over the part to be machined.

The new solution will be presented at the TECHNOLOGY DAYS event from 12-16 November at its BIMATEC SORALUCE, the manufacturer´s Excellence Centre in Limburg, Germany.

“One of its main benefits is a better surface finishing in areas where the part is more flexible, and the chance to boost productivity thanks to in-depth passes with no vibration problems. Its user-friendliness, adaptability to various parts and its portability are some of the other advantages of the device”, says Xabier Mendizabal, Head of R+D at SORALUCE.

A complementary solution to boost traditional formulas

DWS, a pioneer development on the market, provides an effective solution for the problems associated with machining slim-format parts. It is an improvement on traditional alternatives such as the design of costly special toolings, or less reliable and less effective solutions.

Dynamic machine damping

Another in-house SORALUCE development the company will be taking to Germany is the DAS+, a smart system which oversees the machining process and selects the best technological alternative to eliminate any chatter that may arise.

DAS+ has a user interface to control realisation of the process and avails itself of several strategies to eliminate chatter such as active damping of the ram, spindle speed tuning by automatic selection of optimum speed, and harmonic oscillation of spindle speed.

The solution, now available for new machines, can be fitted on request to machinery already operational. The system can boost productivity by up to 300%, with 100% cutting capacity through the complete workpiece volume.

DAS+ also improves the surface quality of the parts produced, extends tool life, makes processes sturdier and reduces wear of the machine´s internal components.

Optimization of machining processes

In addition to DWS or DAS+ products, SORALUCE offers customised advisory services aimed at improving the stability of the machining processes. It consists of the study of existing machining methods and strategies, an analysis to determinate the origin of the vibrations and the approach of solutions to deal with chatter problems that may appear during machining.

SORALUCE´s value proposal in the field of elimination of vibrations will form part of the technology offer the company will be displaying at TECHNOLOGY DAYS, an event to showcase the company´s latest attractions to boost the competitiveness of manufacturing processes.

These are the 8th Technology Days, which serve as a meeting point for leading specialists and manufacturers in the sector.