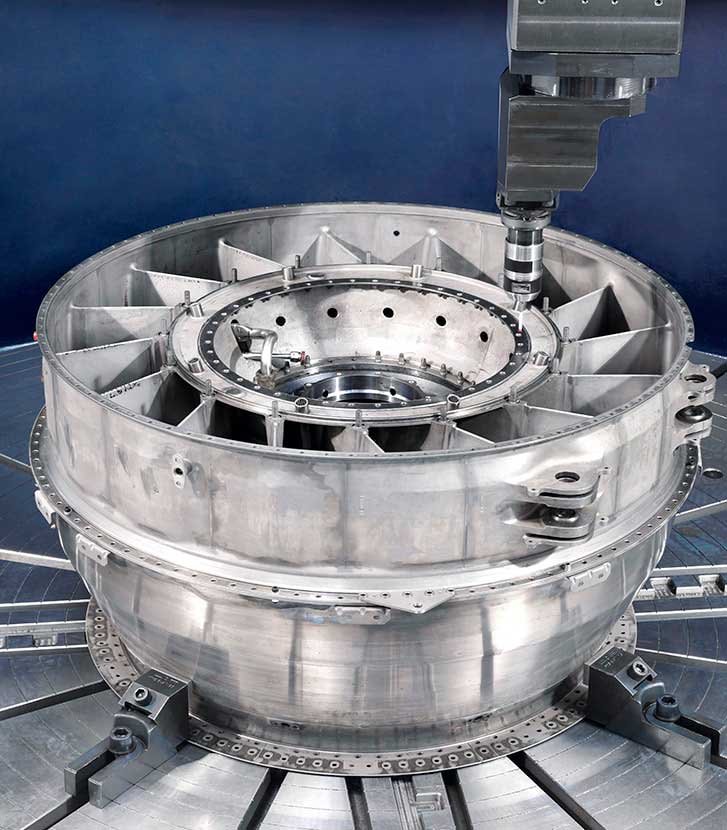

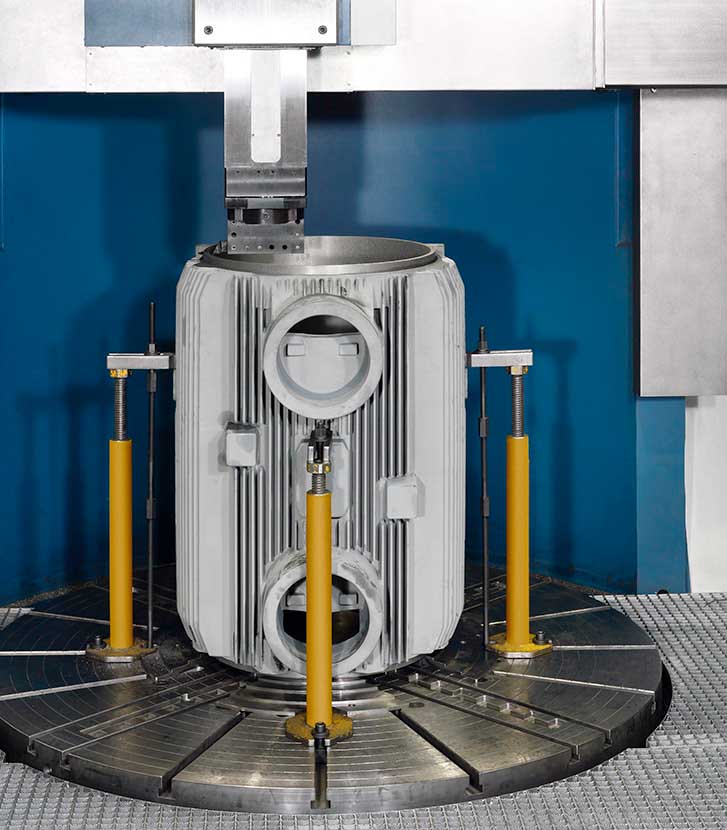

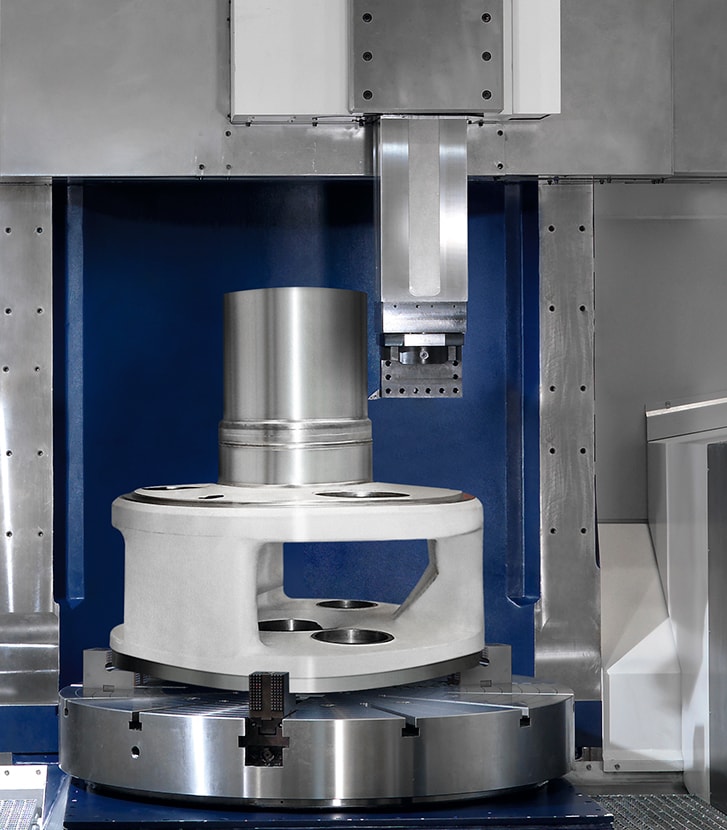

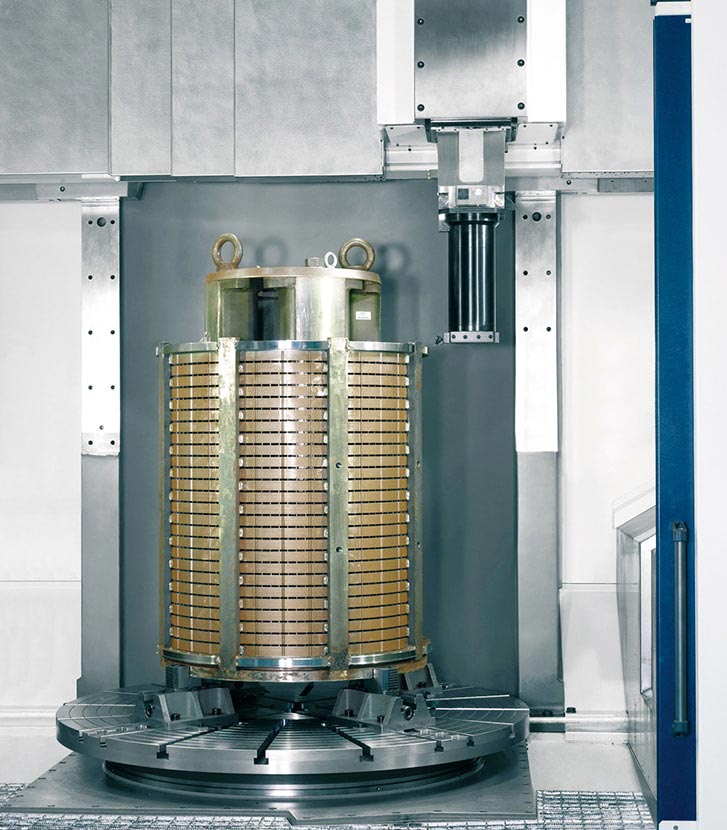

SORALUCE VTC vertical lathe

- Avant-garde high precision multitasking machine.

- Advanced SORALUCE technology geared towards maximising productivity: DPS System and Chip Breaker.

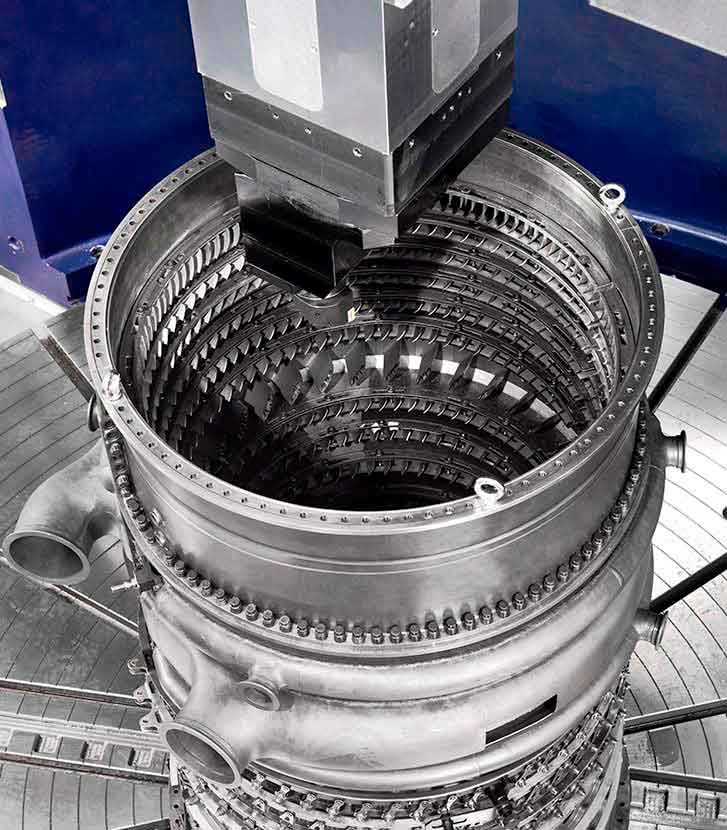

- Multitasking machine: a turning and milling solution in a single set-up

- Automated solutions: integrated palletised workpiece loading and unloading systems and robot-based solutions

- SORALUCE head technology: a highly reliable, extensive range of SORALUCE tool holders and heads

- Automatic head and tool changing systems

- SORALUCE Digital, Data System: comprehensive monitoring package with continuous information of machine and process status

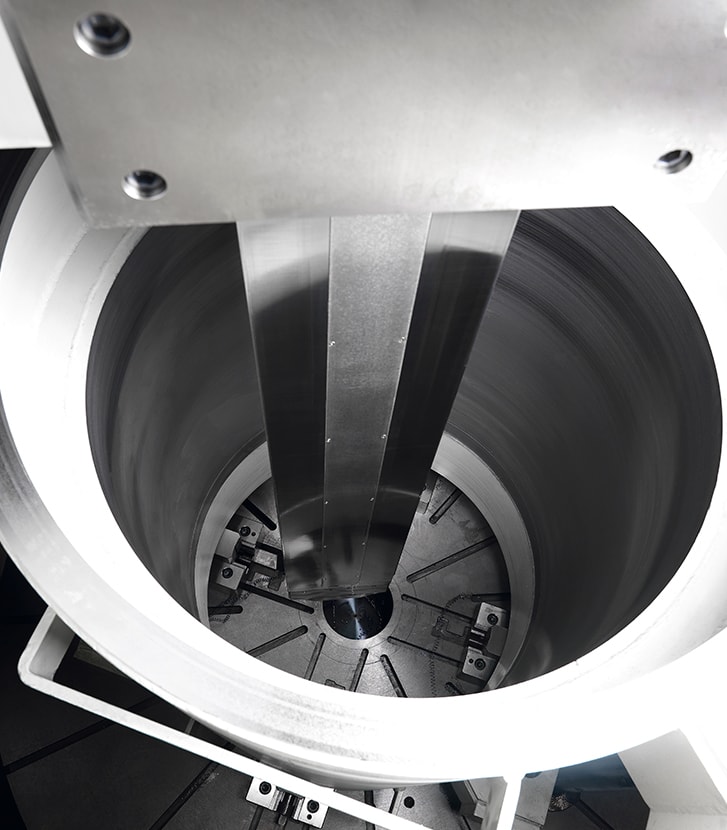

- High productivity results incorporating a double RAM for improved chip removal

- Excellent machining results regarding dimensional accuracy and surface finish

- High thermal stability

- Improved stability to enable high stock removal for components belonging to the aerospace, railway, energy generation, high precision ball bearing, mining, valve manufacturing and outsource and maritime sectors

- Flexible machine: the vertical travel of the traverse enables the machining of short and high workpieces

- Total machine concept design: complete working area analysed for optimal comfort, safety and ergonomics (maintenance spots, operator area)

|

Characteristics |

VTC | |

|---|---|---|

|

Table diameter |

mm |

1800 / 2100 / 2400 / 2800 / 3500 4000 / 5000 / 7000 |

|

Turning diameter |

mm |

2100 / 2500 / 2800 / 3500 / 5000 / 6000 / 8000 |

|

Table speed range |

min-1 |

320 / 260 / 200 / 175 / 100 / 80 / 60 / 35 |

|

Table spindle power |

mm |

57 / 81 / 105 |

|

Table capacity |

mm |

17000 / 20000 / 25000 / 30000 / 5000 / 80000 / 100000 / 150000 |

|

Vertical traverse Ram "Z" axis |

kW |

1500 / 2000 |

|

Cros traverse "X" axis |

min-1 |

2470 / 2870 / 3330 / 3730 / 4600 / 5600 / 6600 / 8800 |

|

Vertical traverse cross beam "W" axis |

mm/min-1 |

800 / 1000 / 2000 / 3500 |

|

Live spindle power |

No. tools |

30 / 37 |

|

Vertical traverse cross beam "W" axis |

min-1 |

3000 / 2000 |

|

Live spindle power |

No. tools |

18 / 2 x 18 / 30 / 18 + 30 |

Customisation

Select your head:

Technical data

SORALUCE offers a wide range of tool holders positioned by a Hirth coupling and locked in place by 4 hydraulic clamping devices, thus ensuring a high degree of repeatability and smooth, leakage-free coolant and fluid recirculation.

- Axial

- Radial

- Annual

- 4 turning tools in 1 heads

- Eccentric milling head

- “Y axis head

- “B” axis head