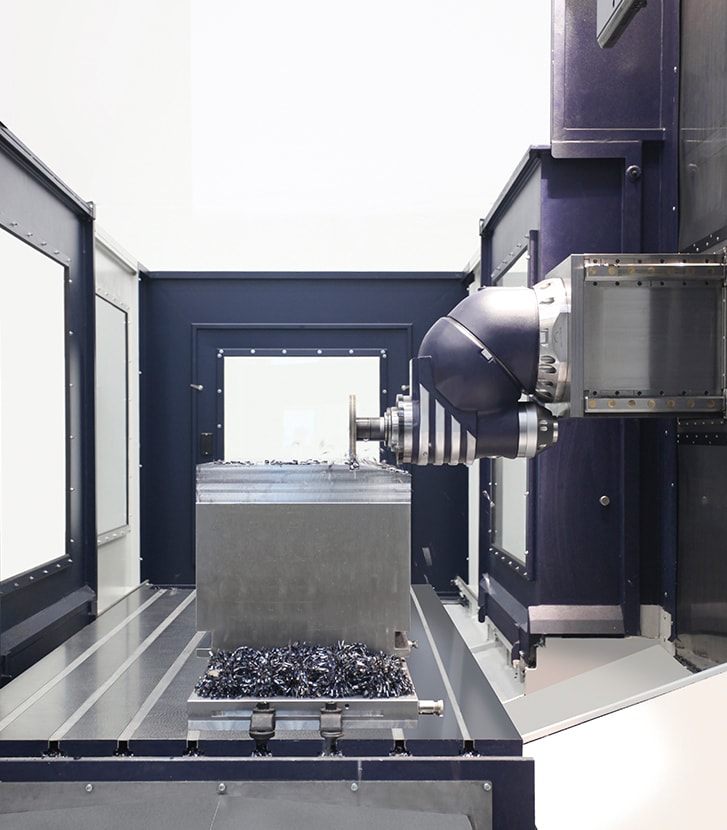

SORALUCE TR bed type milling machine

- High performance and advanced technology in a compact machine.

- Advanced SORALUCE technology geared towards maximising productivity, precision and customisation: DAS+, Accura Heads, SSV and Adaptive Control

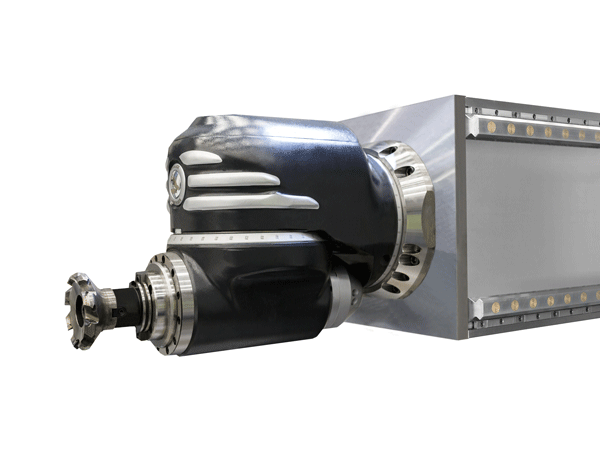

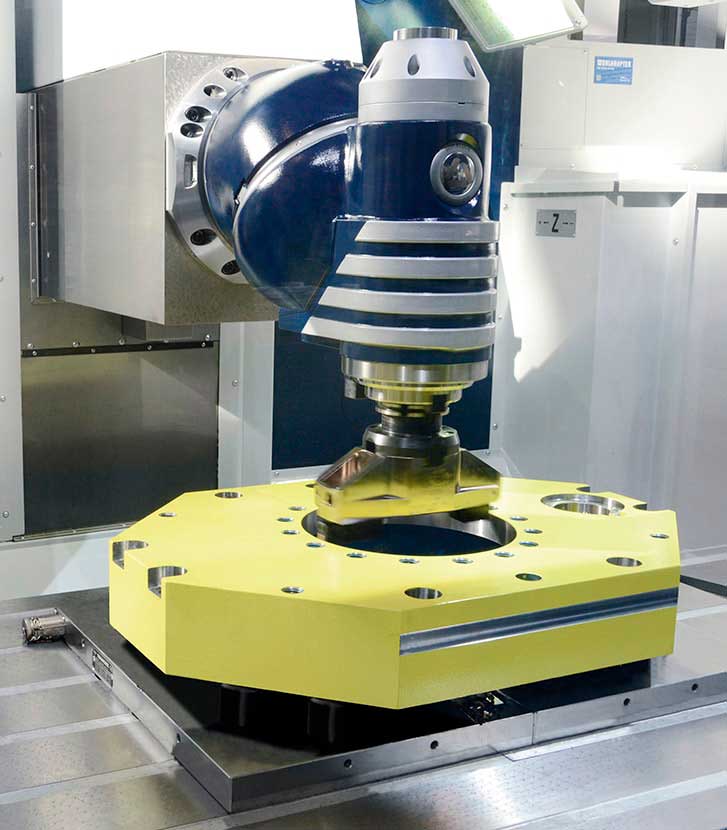

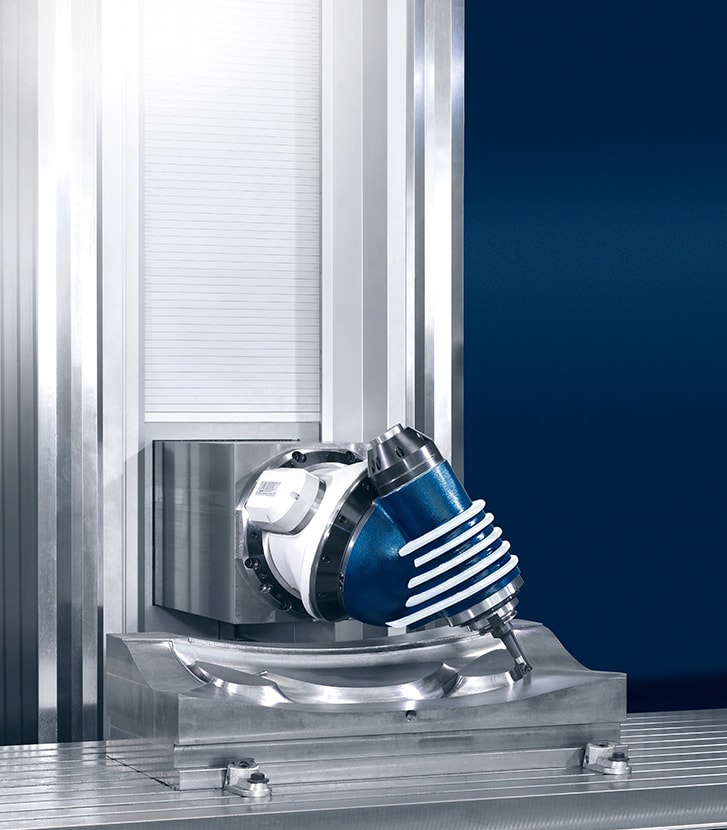

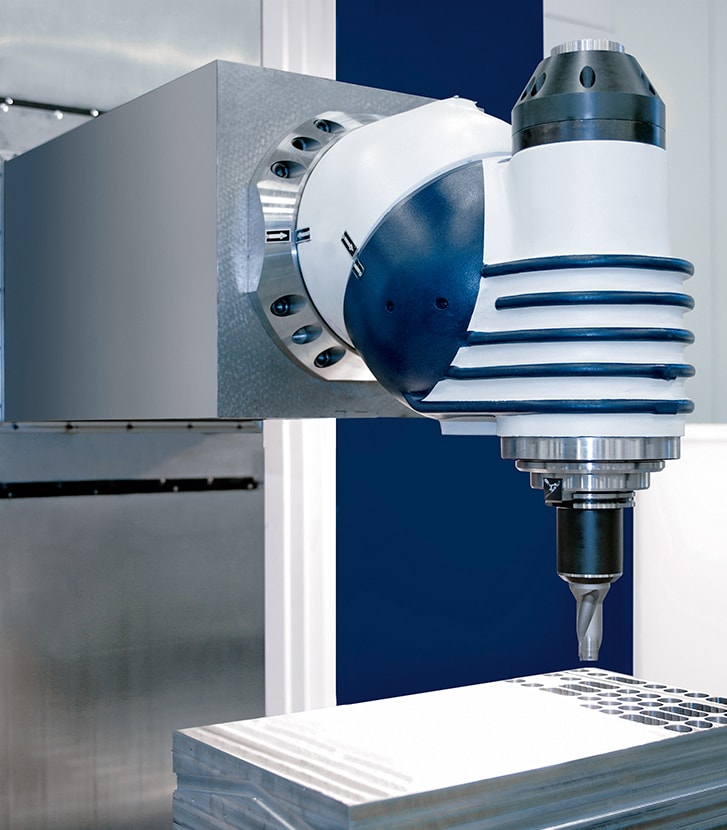

- SORALUCE head technology: a highly reliable extensive range of SORALUCE heads

- Automatic tool changing system

- SORALUCE Digital, Data System: a comprehensive monitoring package with continuous information of machine and process status

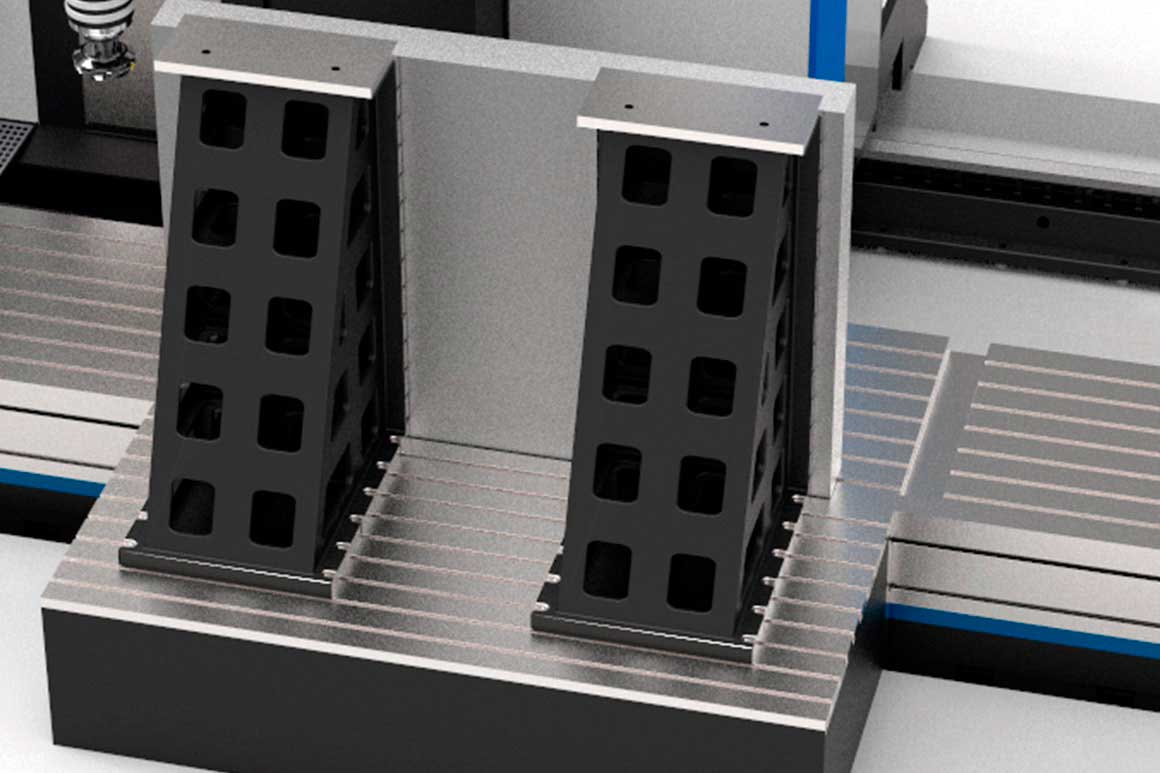

- Long-lasting precision, resulting from a strict design and assembly process

- Optimal stiffness and mechanical stability, providing high stock removal capacity for roughing operations

- Great precision and efficiency with the high torque, direct drive spindle motor

- High dynamics with speeds of up to 35 m/min, acceleration of 2 m/s2 and working feed force of 16000 N on all axes

- Enhanced productivity and precision for components belonging to the moulds and dies and precision engineering industries

- Total machine concept design: complete working area analysed for optimal comfort, safety and ergonomics (maintenance spots, operator area)

|

Characteristics |

TR 25 |

TR 35 |

TR 45 | |

|---|---|---|---|---|

|

Table area |

mm |

2860 x 1200 |

3860 x 1200 |

4860 x 1200 |

|

Table capacity |

mm |

7500 |

10500 |

13500 |

|

Longitudinal traverse "X" axis |

mm |

2500 |

3500 |

4500 |

|

Vertical traverse “Z” axis |

mm |

1600 |

||

|

Cross traverse “Y” axis |

mm |

1300 / 1500 |

||

|

Spindle power |

kW |

43 |

||

|

Spindle speed range |

min-1 |

6000 / 7000 |

||

|

Rapid traverse |

mm/min |

35000 |

||

|

Tool magazine |

No. tools |

40 / 60 / 80 |

||

Customisation

Select your head:

Technical data

It enables for:

- Automatic indexing of vertical and diagonal articulations.

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system.

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- 32 / 43 / 46 / 55 kW

- 2.5° x 2.5° / 1° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 / 6000 / 7000 min-1

Technical data

Its compact design is specially conceived for machines with an in-line motor. It allows the simultaneous positioning of both head articulations, reducing non-production time.

Inverse machining capability:

- Up to -45º

- No additional setups

- Improved cycle time

- Better finishing quality

- Minimum manipulation

- Full advantage of machine travel

- No need for additional work piece support fixtures

- Close to table head spindle accessibility for both front and lateral milling

- 37 / 43 kW

- 1º x 1º

- 4000 min-1